Case Study: MnDOT rebuilds Gateway to Greater Minnesota by going digital

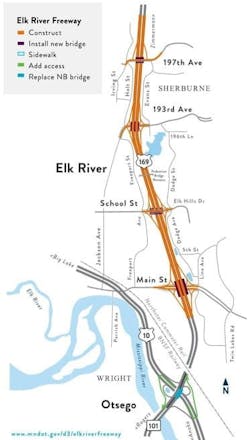

The Highway 169 corridor is an important north-south arterial route in central Minnesota that connects the central great lakes region and the greater Twin Cities metro area with the growing trade centers of Elk River, Zimmerman and Princeton. As part of the state of Minnesota’s Corridors of Commerce program, the Minnesota Department of Transportation (MnDOT) initiated the redesign and reconstruction of a three-mile stretch of Highway 169 through Elk River, converting it to a freeway. The signalized intersections along this section of the roadway are over capacity, resulting in significant delays and safety issues. Heavily traveled by both vehicles and pedestrians, the highway is being renovated to improve safety and reduce the average rate of collisions in the area.

The reconstruction will address operational, infrastructure and mobility issues by replacing the signalized intersections with interchanges, consolidating access points, and renovating local roadways to create accessible routes at the new interchanges. MnDOT contracted WSB to provide and oversee final design of the project, which included converting four signalized, at-grade traffic intersections into interchanges, upgrading and relocating utilities and underground infrastructure, and designing roadway, drainage, and bridge elements.

Upon completion, the new freeway is expected to reduce roadway delays by more than 1,000 hours per day and eliminate USD 1.7 million in annual crash costs, transforming access throughout the Greater Minnesota area.

Cost caps, coordination and complicated earthworks calculations

As a specially funded project through the state’s Corridors of Commerce program, WSB had a guaranteed maximum price (GMP) construction cap of USD 130 million that could not be exceeded. To stay on budget and accommodate the complicated earthworks, WSB needed the design process to be iterative and flexible and enable real-time material quantities to be provided for accurate cost analysis.

The Highway 169 corridor is an important north-south arterial route in central Minnesota that connects the central Great lLkes region and the greater Twin Cities metro area with the growing trade centers of Elk River, Zimmerman, and Princeton. [Image courtesy of WSB]

Compounding the challenging earthworks engineering and strict budget, the project is also being executed as a CMGC project, integrating the construction manager and general contractor (CMGC) into the design process. While this allows for a more collaborative approach early on in the project, it involves coordinating numerous stakeholders, team members, and MnDOT throughout design and construction.

“When fully utilized, the CMGC design process allows for a more collaborative work environment between designer and contractor; however, we need to ensure the CMGC process is efficient, effective, and economical for construction,” said Peter Muehlbach, project manager at WSB. Faced with these technical, financial, and coordination challenges, WSB realized they needed to advance engineering design methods and procedures to utilize 3D models, implement collaborative digital workflows, deliver paperless designs, and generate a digital twin.

Leveraging Bentley’s integrated-technology applications

WSB selected the Bentley iTwin platform and Bentley’s open modeling, visualization, and construction-simulation applications, including ContextCapture, OpenRoads, and ProjectWise, to establish a connected-data environment and collaborative digital workflows. Leveraging these state-of-the-art technologies, they developed sustainable solutions during the design phase that can be utilized throughout the lifecycle of the project.

WSB worked with Bentley to develop the workspaces, standards, and templates for the 3D elements. They then generated the 3D models and used the digital models and software to perform clash-detection to check their design and ensure buildability. Using Bentley’s web-based applications provided an integrated platform to share and communicate the 3D BIM models and digital designs during weekly team meetings. “Bentley has allowed for a more cooperative and collaborative process between the project team and all the project stakeholders,” said Jon Chiglo, COO, WSB. “We leverage these tools to communicate challenging design constraints at our internal and external meetings to ensure this culture of collaboration and sharing encompasses the entire team.”

Working in a connected digital environment using the 3D BIM model, they created a seamless workflow from design through construction that allows information to be imported and accessed digitally, improving communication with the field. Combining the 3D model with the CMGC contractor schedule, they created a 4D model using SYNCHRO that identified exactly how the contractor was going to build the roadway over time. The 4D-modeling strategy streamlined construction management, drainage and utility-relocation processes, and enabled cost-efficient design solutions to accommodate CMGC price changes. Without Bentley’s integrated-modeling applications, the team would not have been able to provide a fluid transfer of design and material quantities to the CMGC, which is an important aspect of adhering to the GMP.

Digitalization sets industry benchmark

The combination of the 3D BIM model, 4D model, and 5D cost structure within a digital-design environment has led to

The team was able to relocate 58.7 miles of utilities 18 months ahead of schedule utilizing clash-detection tools. By creating an accurate reality mesh of the existing conditions using ContextCapture, they finalized construction limits earlier, enabling the right of way process to start two months earlier than planned. [Image courtesy of WSB]

many cost savings and benefits, per stakeholders. Using Bentley’s BIM, reality modeling, and construction simulation applications helped save the client over USD 12 million, with an anticipated ROI of 15-18 million in early 2022. The team was able to relocate 58.7 miles of utilities 18 months ahead of schedule utilizing clash detection tools. By creating an accurate reality mesh of the existing conditions using ContextCapture, they finalized construction limits earlier, enabling the right-of-way process to start two months earlier than planned. Synchronizing the 3D model with 4D-construction scheduling identified potential construction conflicts that accelerated construction activities by three months to save USD 485,569.

Using the Bentley iTwin platform to create a digital twin early in the engineering process provided a true, virtual representation of what will be built, allowing stakeholders to easily review the project impact. “The 3D model allows us to see the design in a whole new light. We are able see design changes on the fly and that provides MnDOT with greater flexibility in the decision-making process,” said Darren Nelson, project manager with MnDOT. Once construction is complete, the project will have an as-built, accurate digital-twin model that can be used for asset management in the future.

In August 2021, WSB delivered the first paperless roadway construction plans to MnDOT. It is MnDOT’s first project using digital delivery. With many departments of transportation across the United States still requiring traditional plans, the project has paved the way for digitalization within the industry. “The innovation and technical creativity of the TH 169 Redefine-Elk River design team, led by WSB, has raised the bar for the future of 3D modeling, visualization, and cross-discipline project coordination in Minnesota,” said Chiglo.