What are on-site digital champions & how can they help you make smarter decisions?

Your current industrial data only tells a partial story. When data is lost, valuable opportunities slip away, resulting in revenue loss. This is precisely why an on-site digital champion for your manufacturing facility is becoming crucial. The digital champion can drive your operation toward a more integrated way of working, fostering a forward-thinking mindset that brings numerous additional benefits along the way.

An on-site digital champion is a highly skilled professional who possesses extensive knowledge and expertise in digital technologies and their practical applications within the manufacturing environment. The role involves providing valuable insights to optimize the digital tools already available to you. Furthermore, the digital champion may recommend the acquisition of additional tools to enhance your overall digital capabilities, always keeping outcome-driven targets in mind. Lacking such an expert on staff can create all sorts of problems. Amit Saluja, vice president and head of digital and innovation, RPG Group, states, “The problems include apprehensions in adopting technology, lack of knowledge of when, where and how to start digitalization, and the inability to replace automation with digitalization.” In fact, without a digital champion on deck you run the risk of trading platforms but not necessarily evolving your processes. This defeats the purpose of digital transformation.

What are the most appropriate background and skills for the digital champion? While the IT field immediately comes to mind, we should cast a wider net. For example, since digital transformations always expand the use of enterprise-wide data, data-science skills have emerged high on the priority list. The digital champion could even have a process-control background, ideally including experience with digital transformations in which there was considerable integration of data and software.

The digital champion’s skillsets will also be very broad. The individual will manage programs and perform assessments of the company’s digital maturity and digital-transformation maturity. Knowledge of the corresponding maturity models is essential. Technical skills should extend to AI, cloud, digital twins, edge computing and even robotics.

HR skills could also come in handy, since true digital transformations are workforce transformations. Knowledge of employee practices and workplace processes will help, considerably, as the digital workforce evolves.

Integrating your operations and converting them into shared data sources provides examples of the integration benefits a digital champion can deliver. With an in-depth knowledge of the intricacies of your specific manufacturing operation, this individual can facilitate operations integration better and more intuitively than someone from outside the organization. The digital champion will also be able to identify key areas such as process control and safety, where digital solutions can be implemented effectively, and then tailor them to meet your organization’s specific needs.

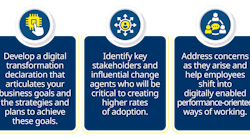

Change-management is a key component of digital transformation, since a successful on-site digital champion will usher in successful changes. Digital technologies often require radical shifts pertaining to workflows, processes and even company culture. A digital champion can play an important role in helping to facilitate these changes by communicating the benefits of the digital tools. This person will also be able to:

· Develop a digital-transformation declaration that articulates your business goals and the strategies and plans to achieve these goals

· Identify key stakeholders and influential change agents who will be critical to creating higher rates of adoption

· Address concerns as they arise and help employees shift into digitally enabled performance-oriented ways of working

If any issues or problems arise with digital tools or applications, the presence of an on-site digital champion ensures prompt assistance, eliminating the need to wait for off-site vendors or engineers. The digital champion can provide immediate support, diagnose problems, and collaborate with relevant stakeholders to identify solutions. This proactive approach minimizes both downtime and potential disruptions, enabling a swift resolution to any digital-related challenges.

Additionally, an on-site digital champion possesses the capacity to elevate the training and skill-development of your employees. This individual can take the lead in organizing digital-literacy workshops aimed at enhancing the capabilities of your manufacturing staff. Through these workshops, employees' knowledge and skills will be enhanced, enabling them to effectively utilize digital tools, which, in turn, will result in further improvements in productivity and efficiency.

In addition, a digital champion actively explores avenues for enhancing processes and capitalizing on emerging technologies. As an example, he or she may conduct a smart-industry-readiness-index (SIRI) assessment, a comprehensive evaluation that measures your business's performance across vital dimensions of operation. The SIRI assessment is recognized as the official Industry 4.0 readiness index endorsed by the World Economic Forum, aiming to assist manufacturers in initiating, expanding and sustaining their journeys toward Industry 4.0 transformation (according to McKinsey & Company). By conducting such assessments, a digital champion ensures you stay ahead of the curve in terms of adopting cutting-edge technologies.

By harnessing the power of digital technologies, a digital champion has the ability to discover various avenues for cost-optimization. These may include minimizing waste, enhancing energy efficiency, and improving supply chain management. Such endeavors have the potential to generate substantial cost savings throughout the lifespan of your facility. Moreover, optimizing plant efficiency will contribute to achieving the sustainable-development goals set for your plant.

Overall, an on-site digital champion empowers your manufacturing operation to effectively harness the potential of digital technologies, driving innovation, efficiency and competitiveness in today's rapidly evolving digital landscape. Hopefully, I have made a solid case that enables you to drive better decisions with a digital champion on-site. In addition, we recommend working with a SIRI assessor to provide a benchmark unique to your business regarding Industry 4.0 and provide a framework that will help you increase digital maturity across your organization, your operations and your people.