Why you should simplify your energy-network monitoring

HMS Networks' Christine Sedelnick

Monitoring an energy network is nowhere near as straightforward as it used to be. Smart-grid development has paved the way for distributed energy resources (DERs), and the resulting interconnectivity has expanded the responsibilities for both transmission system (TSO) and distribution system operators (DSO). While smart grid technology gives operators increased control and measurement of their systems, it also makes digitalization a necessity in power plants and substations.

Having data available solely in the control room is no longer sufficient. There is a need to monitor transformers remotely and implement new maintenance concepts from anywhere. Retrieving building data and optimizing utilization online is now the desired standard—albeit a complex one.

Graphic courtesy IRENA (2019), Innovation landscape brief: Future role of distribution system operators, International Renewable Energy Agency, Abu Dhabi

An increase in data streams

There are two main data streams that operators deal with:

1) Control data that allows the control room to communicate with the substation or individual devices.

2) Monitoring data which comes from sensors, devices, or the substation and is delivered to the control room. While real-time communication is not necessarily required, the data packages are usually more extensive for monitoring data. The data currently transmitted along monitoring paths includes temperatures of transformers, high-voltage lines and motors, or oil pressure in transformers. Transformers, cables, or battery back-up systems can also provide voltage data.

All this information originates from a wide range of sources. Some of it arrives directly from the control computer for the switchgear or measuring devices in the station. Other data points are provided by additional sensors that are commonplace in the industrial environment or in building management. When combined with the management of data and energy contributed from end consumers, adjusting operator roles accordingly can be overwhelming.

The volume of data that operators will have to manage will only increase over time. According to the US Department of Energy, the smart grid in the United States “will consist of millions of pieces and parts—controls, computers, power lines, and new technologies and equipment.”

However, overseeing all of this doesn’t need to be complicated.

Gathering and forwarding data

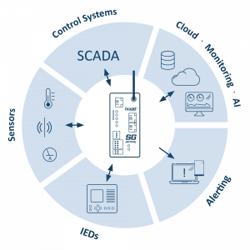

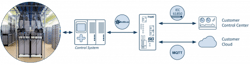

So how can operators gather all this data together to manage it efficiently? There are now gateways available that are designed specifically for this task. These gateways combine the functionality of remote terminal units and controllers, allowing customers to easily digitize substations and distribution networks. Existing systems, new devices, and control systems can all be connected quickly—regardless of the communication technology or manufacturer.

The gateways operate by collecting the data provided by the various sources through relevant physical interfaces. Gateways can be designed to support the communication protocols used in the desired energy sector, but they can also simultaneously feed in the data from sensors connected through alternative protocols, such as Modbus-TCP.

Next steps

Configuration of these types of gateways does not require any programming knowledge or additional software. A sensor manufacturer can use the gateway as a platform for communication with its private cloud, for remote monitoring, surveillance, and maintenance planning. Substations can easily digitize the energy supply, with the gateway feeding the measured data into the control system.

It can then be forwarded directly to the cloud via an integrated LTE modem where it will remain available for continual status monitoring.

And the best part: thanks to the ability to retrofit, older existing facilities can easily benefit from the new possibilities of digitalization.

By HMS Networks' Junior Marketing Specialist Christine Sedelnick